■Purpose

Currently, customers to which we propose digital energy include supermarkets, factories, and nursing care facilities.

Among these, manufacturing factories, which have large areas and consume enormous amounts of electricity, are considered to be the most suitable targets for digital energy.

We investigated what kind of initiatives are being taken at the factory.

■To reduce factory power costs...

1. Introduction of new electricity

By signing a contract with a new power company that is cheaper than your current power company, you can reduce your overall electricity bill.

It is the easiest energy saving measure to implement as it does not require any installation costs.

2. Introduction of self-consumption solar power generation

① Reduce the cost of purchased electricity

Since we generate our own electricity, we can reduce the cost of purchasing electricity.

② Reducing high daytime electricity bills

Since electricity is generated during the day, electricity costs can be reduced when electricity costs are higher than at night.

③ Reduce basic charges

The basic electricity rate is determined by the amount of electricity purchased during the period of highest consumption over the past year.

By reducing the amount of electricity purchased during the day, it will also lead to lower basic charges.

→Useful for BCP measures, CSR, and strengthening corporate competitiveness

Not only energy saving, but also measures against disasters (BCP measures) and environmental initiatives.

This will also lead to increasing CSR and the competitiveness of companies.

3. Demand control using storage batteries

Storage batteries introduced for BCP measures can also reduce electricity costs by using demand control.

Electricity charges and basic charges can be reduced by storing electricity at night, when less electricity is being used, and discharging it when the amount of electricity purchased is likely to increase.

→It becomes more effective when combined with sunlight.

4. Change operating hours to night

Energy costs can be reduced by avoiding daytime operation when electricity costs are high and moving it to nighttime.

There are also some difficult aspects, such as rising labor costs.

5. IoTization of equipment and data management

By implementing IoT in production equipment, air conditioning equipment, etc., it is possible to understand the status of electricity usage and take measures to target areas where reductions are needed.

■Efforts to save energy in air conditioning and lighting

1. Introduction of automatic air conditioning management system

Installing an automatic air conditioning management system is a cost-effective alternative to replacing air conditioning equipment.

Since you can save energy just by installing the system, it can be cheaper than replacing it.

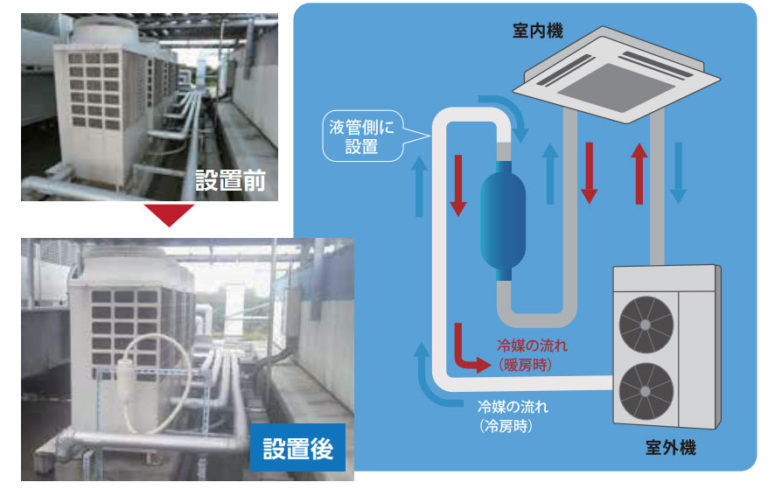

2. Reduce the load on the compressor

The approach of ``reducing the load on the compressor'' can achieve energy savings at a lower cost than automatic management systems.

There are energy-saving devices that can save energy by simply inserting them into pipes without requiring any major construction work. This is a little known method, but

In some cases, energy savings were over 30%.

・Attach equipment to pipes that promotes refrigerant diffusion to reduce the burden on the compressor.

→The power consumption of air conditioners can be significantly reduced.

3. Utilize heat insulating paint and vinyl curtains

Applying heat insulating coatings to roofs and other surfaces will optimize the temperature inside the factory and reduce air conditioning costs. There have even been cases where the temperature inside a factory was lowered by 7 degrees Celsius.

In addition, vinyl curtains prevent outside air from entering, reducing unnecessary air conditioning.

4. Introduction of LED

If you are currently using incandescent lights, simply switching to LEDs will reduce power consumption to 1/5.

For factories that use a lot of lighting, the savings can exceed 1 million yen per year.

Furthermore, if you install LED lighting equipped with a ``motion sensor'', you will be able to save even more energy than regular LED lighting.

The occupancy sensor automatically turns off the lights when no workers are present, which has the advantage of conserving energy frequently even within the area.

■Introduction of cogeneration system

A cogeneration system (cogeneration) is a system that simultaneously produces and supplies two types of energy.

The currently mainstream cogeneration system is called a "combined heat and power system," which first uses a power generation device to generate electricity, then recovers the heat emitted during power generation and uses it for hot water supply, space heating, etc. ing.

Fuels used for power generation include natural gas, oil, LP gas, and biomass.

■Summary

While many companies are working to reduce electricity costs at their factories,

In many cases, efforts are limited, such as ``changing the air conditioning equipment'' or ``promoting the use of LED lighting.''

In other words, by comprehensively consulting on equipment investment, energy conservation, etc., it is possible to significantly reduce costs.

We believe that incorporating our own service ``DigiEne'' into this will become an effective approach to cost reduction.